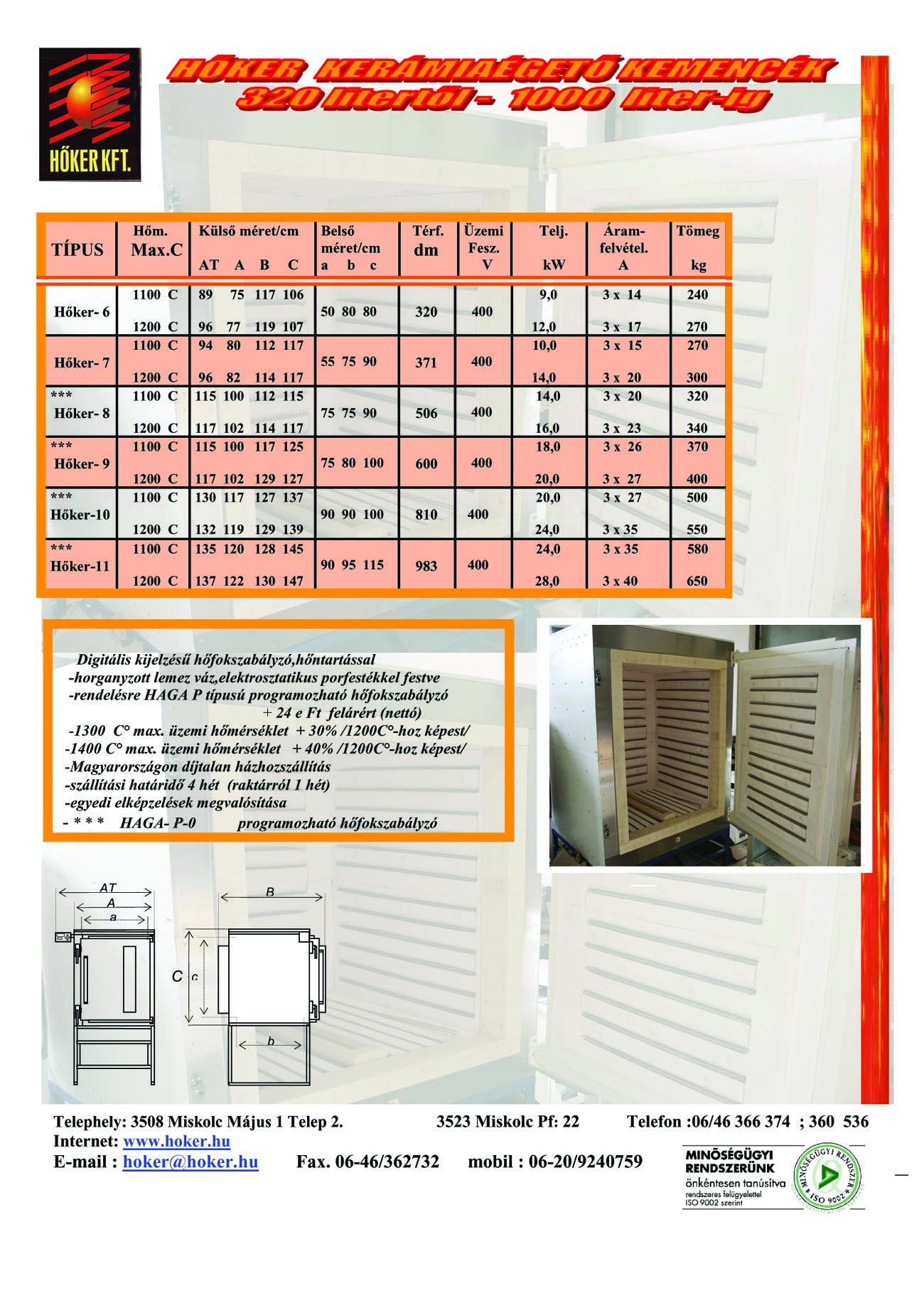

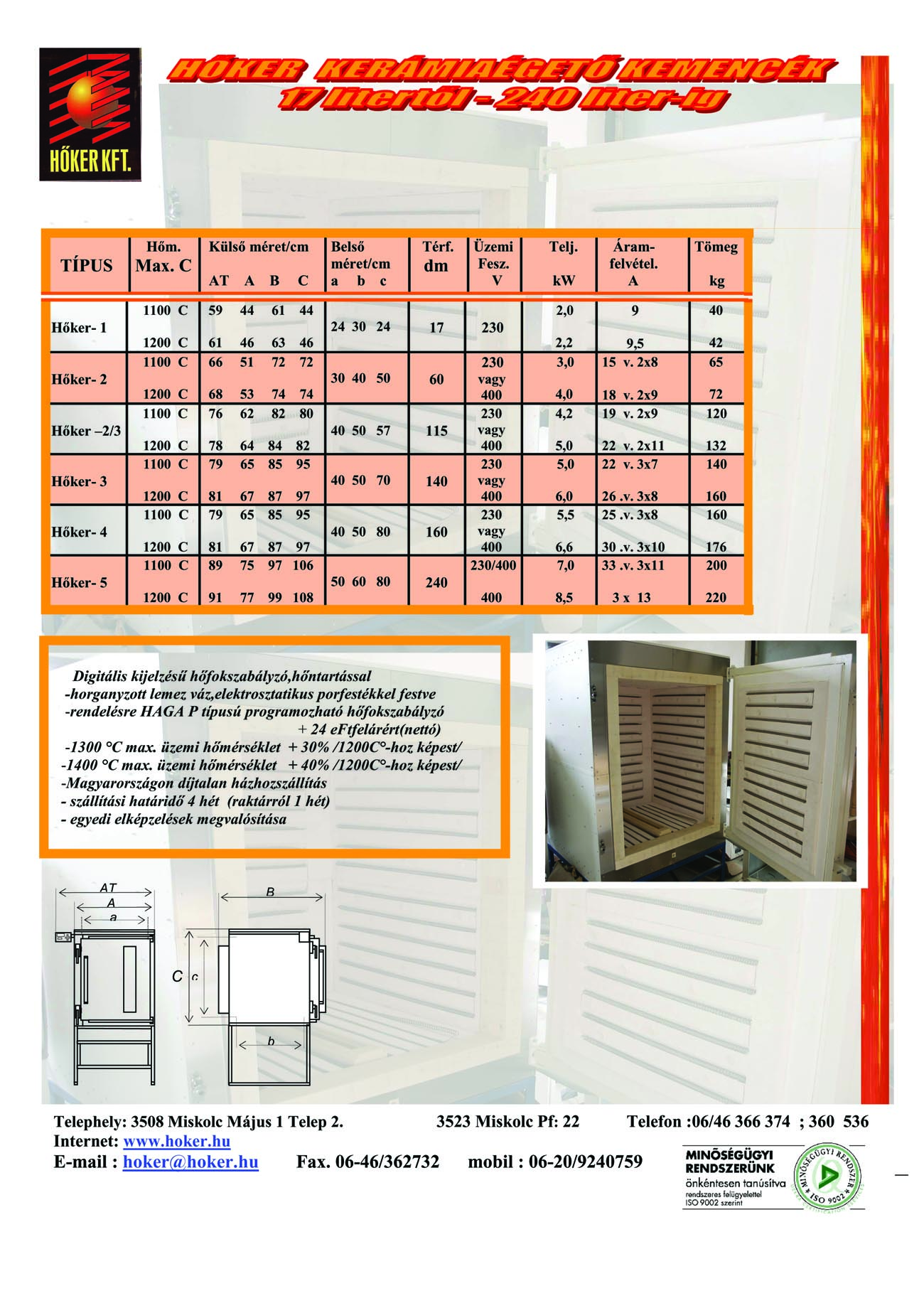

Ceramic furnaces

For firing and heat treatment of various ceramic materials and glass.

Our kilns are built with fiber-ceramic panels and a unique insulation system, providing extremely energy-efficient operation. Larger equipment can be equipped with our own developed side cooling system, allowing for relatively quick cooling without damaging the fired product. This reduces firing time and increases productivity.

For firing and heat treatment of various ceramic materials and glass

Our furnaces are built with fiber-ceramic board linings and custom-designed thermal insulation, ensuring extremely energy-efficient operation. Larger units can be equipped with our proprietary side-cooling system, allowing for relatively fast cooling without damaging the fired products, thereby reducing firing time and increasing productivity.

To meet specific requirements, we also manufacture furnaces with a continuously ventilated – suction-type – firing chamber, equipped with a noble metal catalyst.

Instrumentation is based on the latest microprocessor-controlled devices, allowing for comprehensive heat treatment programs and operation with multiple thermocouples.

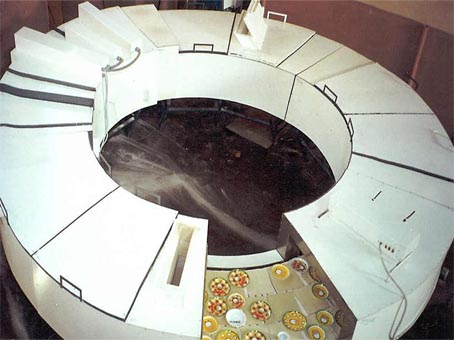

Our continuous-operation round furnaces meet even the highest production demands.

Construction design of ceramic kilns:

- Chamber kiln with side-opening door (standard version with right-opening door and left-side electric cabinet, reverse version available on request)

- Heating from five sides (two sides, bottom, back, door)

- Rear ventilation opening

Temperature control and power control:

- As standard, kilns are manufactured with HAGA KD 48 B1 type digital display instrument

- As standard, power control is done with contactors

- As standard, power control is done with contactors

- Temperature measurement: up to 1200°C with "K" type Ni-CrNi thermocouple, between 1200–1400°C with "S" type Pt-PtRh thermocouple

Optional accessories:

- Front panel made of corrosion-resistant steel sheet

- Lockable ventilation openings in the door

- Drawer design under the kiln floor for enhanced ventilation

- Double-door version for larger kilns to facilitate easier loading and unloading

- Car-bottom kiln design

- Built-in cooling channels in the side walls for faster cooling (recommended for larger kilns)

- Multi-zone heating system for more uniform chamber temperature (typically 2 or 3 zones)

- Instrument-controlled motorized ventilation and cooling doors

Optional list:

- Power switching with solid-state relays

- All instruments can be supplemented with a computer-connectable unit for data storage

- Delivery of calibrated thermocouple and instrument, or a fully calibrated furnace

- Version with 1300 °C operating temperature also available

- Version with 1400 °C operating temperature also available

- Installation of modified electrical power capacity

Delivery conditions:

- Standard delivery time is within 4 weeks, except if the ordered model is in stock, in which case approximately 1 week

- Free home delivery within Hungary; under suitable conditions, this may also apply to neighboring countries

- Written order required, with clear technical specifications

Warranty conditions:

- Up to 1200 °C: 24 months

- Up to 1300 °C: 18 months

- Up to 1400 °C: 12 months

- Temperature controller: 36 months

Brief overview of temperature controllers:

- HAGA KD 48 B1 basic instrument with digital display.

The firing temperature and holding time can be set within a range of 0–150 minutes.

- HAGA KD 24 instrument with digital display.

Programmable by the manufacturer to apply reduced heating power (e.g. 40%) up to the drying temperature,

to set the drying temperature (e.g. 250 °C), and to set the holding time at the firing temperature (e.g. 10 minutes).

The user can only adjust the firing temperature as needed.

- HAGA KD 48 P 0000 programmable instrument.

Programmable features:

- pre-delay time from 0 to 99 hours 99 minutes

- heating rate, temperature, and holding time in two steps

- 1 program can be stored

- HAGA KD 48 P 0001 programmable instrument.

Programmable features:

- pre-delay time from 0 to 99 hours 99 minutes

- heating rate, temperature, and holding time in 2 steps

- 2 different programs can be stored

- HAGA KD 48 P 0002 programmable instrument.

Programmable features:

- pre-delay time from 0 to 99 hours 99 minutes

- heating rate, temperature, and holding time in 8 steps

- 7 different programs can be stored

All "P" type instruments are equipped with an operating hour counter. All HAGA instruments feature a so-called self-tuning PD controller.

Stress-relief and decal-firing kilns:

- Designed for stress-relieving laboratory and decorative glassware

- Typical max. operating temperature: 600 °C

- Corrosion-resistant steel frame in the firing chamber (removable), for supporting ceramic plates

Construction and further information as described for ceramic kilns, with the difference that the installed electrical power is approximately 70% of that of the 1100 °C version, and the thermal insulation is adapted to the 600 °C operating temperature.

English (UK)

English (UK)  Magyar

Magyar